How Reps Shoes Are Made: The Manufacturing Process Explained

In recent times, the desire for high-quality replica shoes commonly known as “reps shoes” has soared. These replicas are designed to look and feel like popular branded footwear but are sold at a fraction of the price of the original items. While people debate the ethics of buying these replica shoes, there is little doubt about the craftsmanship and elaborate process that goes into making one. This article will take an in-depth approach to how reps shoes are made and the step-by-step process behind manufacturing.

What Are Reps Shoes?

Reps shoes are replica branded footwear; it could be Nike, Adidas, Yeezy, and Jordan. It’s designed almost as closely as the real one with identical materials and even the construction technique. The manufacturers are not officially licensed, yet good quality reps can resemble the real deal to a near similarity. Manufacturing reps shoes requires some labor input and the right kind of machines for their making and detail.

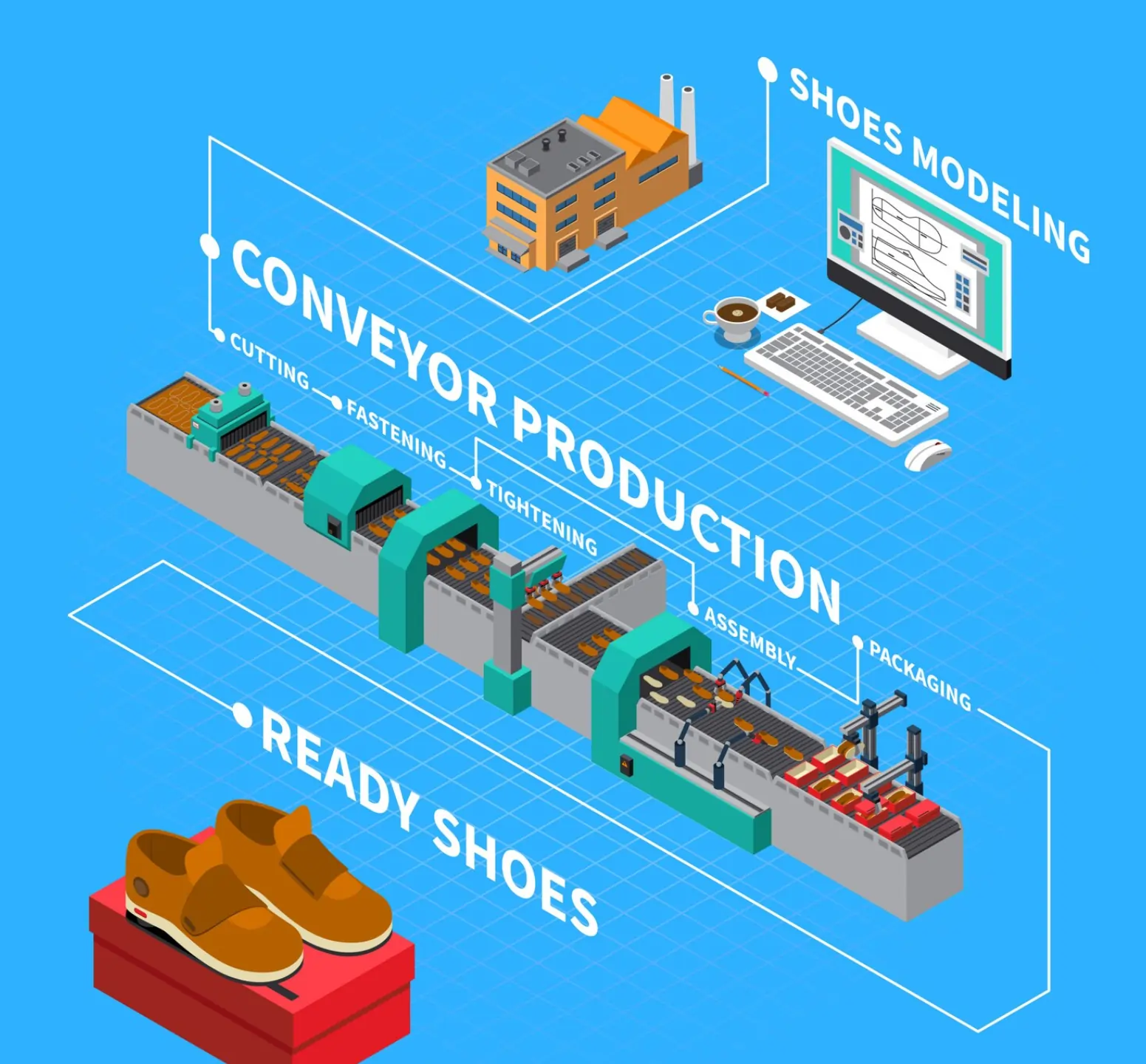

The Manufacturing Process of Reps Shoes

The creation of reps shoes involves several stages, from design and material sourcing to assembly and quality control. Below, we break down the process step by step.

1. Design and Prototyping

The first step in making reps shoes is creating a design that closely matches the original product. Manufacturers often purchase authentic pairs of the shoes they want to replicate. These shoes are then disassembled to study their construction, materials, and design details.

- 3D Modeling: Using the disassembled shoes as a reference, designers create 3D models of the reps shoes. This step ensures that every detail, from stitching patterns to logo placement, is accurately replicated.

- Prototyping: Once the design is finalized, a prototype is created. This prototype is tested for fit, comfort, and durability. Adjustments are made as needed to ensure the final product meets the desired standards.

2. Material Sourcing

The quality of reps’ shoes largely depends on the materials used. Manufacturers source materials that closely resemble those used in the original shoes. This includes:

- Leather and Synthetic Fabrics: High-quality reps shoes often use genuine leather or premium synthetic materials to mimic the look and feel of the original.

- Rubber and Foam: The soles of reps shoes are typically made from rubber or foam, similar to the materials used in authentic footwear.

- Thread and Adhesives: Durable thread and strong adhesives are used to ensure the shoes hold up over time.

Some manufacturers even source materials from the same suppliers as the original brands, further enhancing the authenticity of the reps shoes.

3. Cutting and Stitching

Once the materials are sourced, the next step is cutting and stitching. This is where the individual components of the shoe are created.

- Cutting: Using patterns derived from the original design, workers cut the materials into the required shapes. This process is often done using automated cutting machines for precision.

- Stitching: Skilled workers then stitch the pieces together. This step requires a high level of craftsmanship, as the stitching must be neat and consistent to match the original design.

4. Sole Production

The sole is one of the most critical components of a shoe, and its production is a detailed process.

- Molding: The sole is typically created using molds. These molds are designed to replicate the exact shape and texture of the original shoe’s sole.

- Injection Molding: For rubber soles, injection molding is commonly used. This involves heating rubber and injecting it into the mold to create the desired shape.

- Midsole Construction: The midsole, which provides cushioning, is often made from foam. It is cut and shaped to match the original design.

5. Assembly

Once all the components are ready, the shoes are assembled. This involves attaching the upper part of the shoe to the sole.

- Lasting: The upper part of the shoe is stretched over a last (a foot-shaped mold) to give it its final shape.

- Adhesion: The upper and sole are then glued together using strong adhesives. Some manufacturers also use stitching or heat bonding for added durability.

- Finishing Touches: Details such as logos, labels, and decorative elements are added during this stage.

6. Quality Control

Quality control is a crucial step in the production of reps shoes. Manufacturers inspect the shoes to ensure they meet the desired standards.

- Visual Inspection: Each pair of shoes is visually inspected for defects, such as uneven stitching or misaligned logos.

- Fit and Comfort Testing: Some manufacturers test the shoes for fit and comfort by having people wear them and provide feedback.

- Durability Testing: The shoes may also undergo durability tests to ensure they can withstand regular use.

7. Packaging and Distribution

Once the shoes pass quality control, they are packaged and prepared for distribution.

- Packaging: Reps shoes are often packaged in boxes that mimic the original brand’s packaging. This includes labels, tags, and even dust bags.

- Distribution: The shoes are then distributed to retailers or directly to customers through online platforms.

The Ethics of Reps Shoes

While the manufacturing process of reps shoes is impressive, it’s important to address the ethical concerns surrounding their production and sale.

- Intellectual Property: Reps shoes infringe on the intellectual property rights of the original brands. This can lead to legal issues for manufacturers and sellers.

- Labor Practices: Some reps’ shoe factories may have poor labor conditions, including low wages and long hours. It’s essential to research the ethical practices of manufacturers before purchasing.

- Consumer Awareness: Buyers should be aware that purchasing reps shoes supports an industry that operates outside of legal and ethical boundaries.

How to Identify High-Quality Reps Shoes

For those interested in purchasing reps shoes, it’s important to know how to identify high-quality products. Here are some tips:

- Material Quality: High-quality reps shoes use materials that closely resemble the original. Look for genuine leather, durable stitching, and well-crafted soles.

- Attention to Detail: Check for accurate logo placement, consistent stitching, and proper alignment of components.

- Comfort and Fit: High-quality reps shoes should feel comfortable and fit well, just like the original.